1. Introduction

In Australia’s demanding industrial and construction landscape, selecting the right material for high-temperature and corrosive environments remains a challenge. Traditional stainless steels often fall short when exposed to extreme conditions—leading to premature failures, costly maintenance, and downtime. Whether in chemical processing, marine environments, or thermal applications, industries are in constant search of a reliable solution.

This is where Stainless Steel 321 Sheets step in—offering the high-performance characteristics needed to withstand Australia's harsh environments.

2. Product Introduction

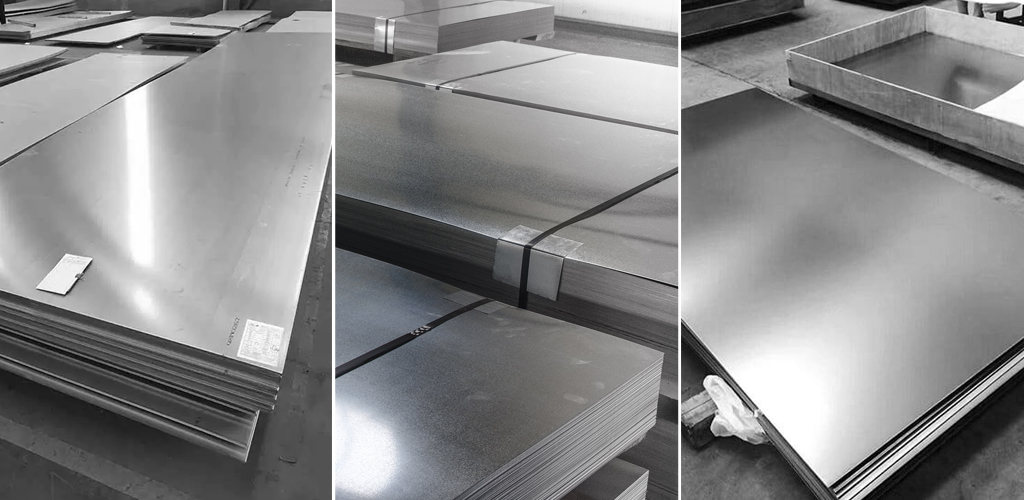

Stainless Steel 321 Sheets are titanium-stabilized austenitic stainless steel products known for their resistance to intergranular corrosion. They are an ideal choice for high-temperature applications, particularly in the range of 500°C to 900°C. These sheets maintain strength and integrity even in prolonged exposure to heat, making them invaluable in industrial and structural applications.

Manufactured in accordance with standards such as SS 321, these sheets meet stringent Australian and international quality benchmarks, ensuring top-tier performance.

3. Advantages Only

High Temperature Resistance: Performs exceptionally in heat-intensive environments.

Titanium Stabilization: Prevents carbide precipitation during welding and heating.

Corrosion Resistance: Especially effective against intergranular corrosion.

Excellent Weldability: Easy to fabricate and weld without risk of cracking or brittleness.

Durability: Long service life reduces the need for frequent replacements.

Low Maintenance: Minimizes costs and downtime associated with upkeep.

Compliance with Standards: Meets SS 321 and other global industrial specifications.

4. Real-Life Uses

Petrochemical and Refinery Plants: Heat exchangers and furnace parts.

Aerospace Industry: Engine components that face high thermal stress.

Food Processing Equipment: Where sanitation and corrosion resistance are vital.

Marine Applications: Suitable for seawater-facing parts and shipbuilding.

Power Generation: Boilers and exhaust systems.

Architectural Applications: For cladding and design elements in coastal buildings.

5. How They Solve the Problem & Outcome of the Product

By offering superior resistance to oxidation and corrosion at elevated temperatures, Stainless Steel 321 Sheets directly address the common failure points found in standard stainless steel alternatives. In Australia, where industries must contend with both thermal extremes and saline coastal conditions, the reliability of 321 stainless steel means fewer repairs, less downtime, and greater structural integrity.

Clients who have switched to Stainless Steel 321 Sheets from conventional materials report extended equipment life cycles, improved operational efficiency, and significant cost savings over time. Whether it’s resisting corrosion on a marine vessel or withstanding furnace heat in a refinery, the outcome is consistent: performance without compromise.

6. Short Conclusion

In Australia's industrial and environmental conditions, selecting the right material isn't a luxury—it's a necessity. Stainless Steel 321 Sheets provide the durability, resilience, and longevity that businesses demand. For those seeking quality and reliability, choosing from trusted Stainless Steel 321 Sheets manufacturers is the first step toward building with confidence.